Wine industry consulting

an analytical mind with a pragmatic approach

passion plus process.

Everyone in our industry is passionate about what we do, but sometimes the passion isn’t enough to succeed – that’s where the process get you through.

Based on over 25 years of experience in multiple industries, I can help you make better wine while keeping that passion alive.

what can i do for you

My services include both detailed and holistic process analyses of your winemaking and business activities. I have a particular interest in reducing waste of both wine and time, which directly lead to improvements in your bottom line.

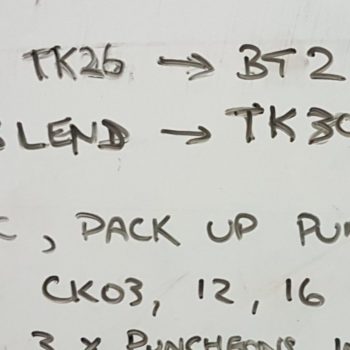

winemaking

With almost 20 vintages working with a wide range of fruit, from hot and cold climates, making everything from sparkling through to fortified wines, I can help you make better wine through an independent, fresh look at all of your activities.

Refrigeration assessment

Don’t wait until vintage to discover you don’t have enough cooling. I can analyse your fruit intake and fermentation plans to assess whether your system can cope. If you are planning on expanding, then this analysis is crucial so you have time to make changes to your system.

product costing

Product costing is essential for setting prices and increasing profits. Using easily implemented tools, we can calculate how much your wine actually costs you to make it, including calculation of growing costs, vintage, ageing, and packaging – this includes tracking those costs across the multiple years from picking to selling.

Management processes

Often all it takes is a fresh set of eyes that knows how wineries work. After years of small winery management, I know the considerable pressures on managers and owners, and can help you streamline the processes to make time for the rest of your to-do list.

wine analysis

Knowledge is everything – the numbers don’t make the wine, but they can let you know what is going on before it becomes a problem. In addition to advising on best practices for wine analysis, I can measure free and total SO2, pH and TA, malic and acetic acids, glucose and fructose, and Yeast Assimilable Nitrogen (YAN). Enzymatic analysis is performed using an automated analyser. Free SO2 is measured using a Sentia handheld analyser – so fast that you can measure individual barrels. pH and TA are measured using an auto-titration system that I built to ensure repeatability and accuracy.

A Different Approach

I combine skills learned as an engineer, winemaker, and manager.

Engineering is about turning ideas into reality, much like winemaking. We seek efficiency through practical, workable, cost-effective solutions.

I bring years of experience, well-developed research skills, and an innate pragmatism to seek out solutions to your problems.